I see so many brands claim their packaging is “biodegradable,” but what does that really mean? I used to wonder if it truly helps the planet or just sounds good on paper.

Biodegradable packaging is made from natural materials that can be broken down by microorganisms into water, carbon dioxide, and biomass, leaving no toxic residue in the environment.

When I first started my eco-packaging business, I wanted to make packaging that actually disappears without harming the earth. Let’s take a closer look at what biodegradable packaging really means and how it works for different industries.

What type of bags are biodegradable?

It’s easy to get confused because so many bags claim to be eco-friendly. But not all are truly biodegradable.

Biodegradable bags include PLA, PBAT, PHA, starch-based, and paper bags that naturally break down under specific environmental conditions.

Dive deeper

There are several common types of biodegradable materials used in packaging:

| Type | Source | Key Features | Common Uses |

|---|---|---|---|

| PLA (Polylactic Acid) | Corn starch or sugarcane | Transparent, strong, food-safe | Food & beverage packaging |

| PBAT (Polybutylene Adipate Terephthalate) | Synthetic biodegradable polymer | Flexible and durable | Mailer bags, shopping bags |

| PHA (Polyhydroxyalkanoate) | Bacterial fermentation | Marine-safe and compostable | Disposable packaging |

| Starch-based blends | Corn, potato, or tapioca starch | Fully biodegradable | Waste and shopping bags |

| Paper | Trees or recycled fiber | Natural, recyclable, biodegradable | Retail and takeaway packaging |

Each type has unique performance benefits. For example, PLA is great for clear food packaging, while PBAT is better for flexible, durable bags. In my factory, we often combine PLA and PBAT to achieve both strength and biodegradability.

What is the best biodegradable packaging?

The “best” packaging always depends on what you pack and where it ends up.

The best biodegradable packaging balances strength, clarity, and environmental safety while meeting product-specific needs.

Dive deeper

When I help clients choose materials, I consider three things: function, environment, and end-of-life impact.

PLA and PBAT blends are popular because they perform like plastic but degrade within months in the right conditions. Paper packaging works well for dry goods and retail, while PHA and starch blends are better for wet or organic products.

| Application | Recommended Material | Benefits |

|---|---|---|

| Food packaging | PLA + PBAT | Clear, strong, and compostable |

| E-commerce mailers | Recycled paper or PBAT | Durable and recyclable |

| Industrial packaging | PHA | High durability and biodegradability |

| Retail bags | Paper or PLA | Elegant, natural look |

Choosing the right material helps reduce waste and ensures that the product lifecycle aligns with sustainability goals.

What is the difference between biodegradable and compostable bags?

Many people think “biodegradable” and “compostable” mean the same thing. They don’t.

Biodegradable bags break down naturally, while compostable bags need composting conditions and leave no toxic residue.

Dive deeper

Here’s how they differ:

| Feature | Biodegradable | Compostable |

|---|---|---|

| Breakdown conditions | Natural environment | Composting facility or home compost |

| Timeframe | Weeks to years | 90–180 days |

| Residue | May leave small residues | No toxic residue |

| Certification | Optional | Requires EN13432 or ASTM D6400 |

Compostable bags must meet strict standards. They turn into nutrient-rich soil within a few months. Biodegradable bags might degrade more slowly and not always fully turn into compost. Both are steps forward, but compostable options are better for circular waste systems.

What material is 100% biodegradable?

I often get asked which material can completely disappear without trace.

PLA, PHA, PBAT, starch-based blends, and kraft paper are 100% biodegradable under suitable environmental conditions.

Dive deeper

These materials decompose completely without leaving microplastics.

For example, PHA, made by bacteria, can even biodegrade in seawater. PLA and PBAT require industrial composting environments. Paper and starch-based bags can break down at home or in soil within months.

Every region has different waste handling systems, so I always recommend materials that suit the customer’s local disposal method.

What are the disadvantages of biodegradable bags?

Biodegradable bags aren’t perfect. I learned this while testing different batches for export clients.

They have shorter shelf lives, may cost more, and sometimes require specific composting conditions to degrade properly.

Dive deeper

Main challenges include:

| Issue | Description |

|---|---|

| Cost | Biodegradable materials are pricier than traditional plastic |

| Shelf life | They start degrading after 6–12 months |

| Performance | Can be sensitive to heat and moisture |

| Composting limits | Some require industrial facilities |

| Consumer confusion | Labels can be misleading |

Still, most clients find these challenges manageable. Over time, material innovation and mass production are reducing costs. Our team constantly works to improve stability and usability.

Are Ziplock bags biodegradable?

It’s a common question, and the short answer is no.

Standard Ziplock bags made from polyethylene (PE) are not biodegradable.

Dive deeper

Traditional Ziplock bags use petroleum-based plastic that can last hundreds of years.

However, biodegradable zipper bags made from PLA or PBAT are available. My factory produces eco zipper bags that perform similarly but decompose naturally in industrial composting conditions.

Switching to biodegradable zipper packaging is an easy way for brands to cut down plastic waste without losing functionality.

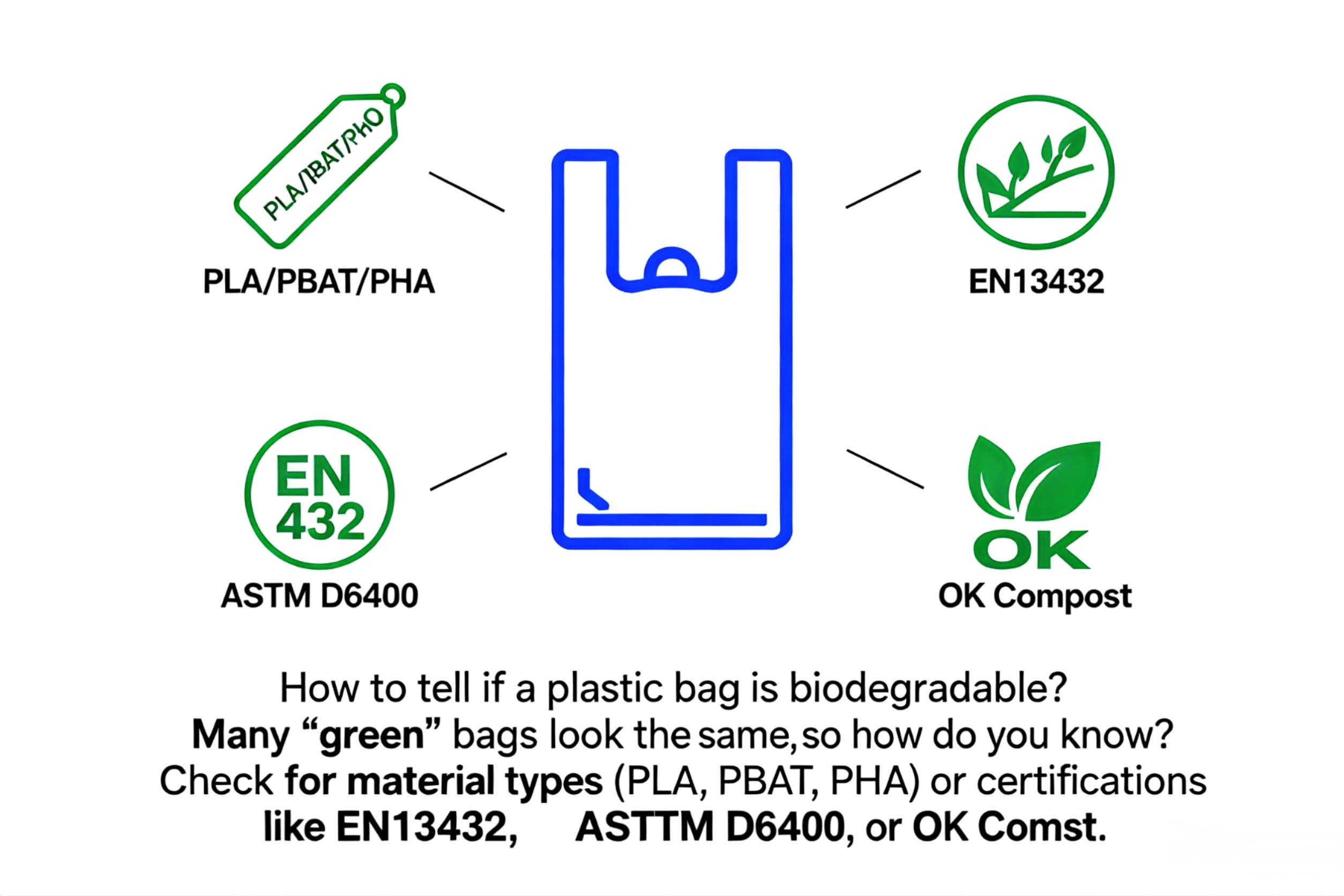

How to tell if a plastic bag is biodegradable?

Many “green” bags look the same, so how do you know?

Check for material types (PLA, PBAT, PHA) or certifications like EN13432, ASTM D6400, or OK Compost.

Dive deeper

Here’s a checklist:

- Look for certification logos.

- Check the material description.

- Ask your supplier for test reports.

- Observe how the bag behaves over time in compost or soil.

In my experience, genuine biodegradable materials feel softer and decompose faster in humidity or sunlight. Always verify certification to ensure compliance with your market’s sustainability standards.

How long do biodegradable bags last?

Clients often worry about storage time before the bags start breaking down.

Biodegradable bags last 6–12 months in storage and decompose within 3–6 months under composting conditions.

Dive deeper

Storage environment affects lifespan. If stored in cool, dry places away from sunlight, they can last up to a year.

Once exposed to moisture, heat, or microbes, the material begins to degrade. This process ensures environmental safety but requires proper handling in warehouses.

Our factory uses advanced sealing and packaging techniques to maintain material stability during long shipping periods.

What are the problems with biodegradable packaging?

Biodegradable packaging sounds perfect, but it has real challenges in global supply and waste systems.

Problems include limited composting infrastructure, higher cost, and confusion between biodegradable and recyclable products.

Dive deeper

Many countries still lack industrial composting systems. As a result, biodegradable materials often end up in regular landfills, where oxygen is low, slowing down the decomposition process.

There’s also confusion among consumers—some throw biodegradable bags into recycling bins, contaminating recyclable waste streams.

As a manufacturer, I focus on clear labeling and customer education. Proper disposal is just as important as material innovation.

Can biodegradable bags go in food waste?

It depends on certification and local waste management systems.

Certified compostable bags can be placed in food waste bins, but non-certified biodegradable bags should not.

Dive deeper

Many composting facilities only accept bags that meet EN13432 or ASTM D6400 standards. These break down safely and leave no toxic residue.

When exporting to Europe or Australia, my clients often require OK Compost or home-compost certification.

If your biodegradable bags don’t carry certification, they should go into general waste or organic waste collection points.

Are supermarket bags biodegradable?

Most supermarket bags are still made from conventional plastic.

Unless labeled otherwise, supermarket bags are usually HDPE or LDPE, which are not biodegradable.

Dive deeper

Some eco-conscious supermarkets now offer PLA or PBAT-based alternatives.

These new bags have similar strength but naturally degrade.

As more retailers move toward sustainability goals, demand for biodegradable shopping bags continues to rise.

PackagingMC provides bulk supply for such projects with customizable designs and logos.

What can I use instead of food waste bags?

You can manage food waste even without plastic-looking bags.

Use newspaper liners, compostable paper bags, certified compostable PLA/PBAT bags, or no bag at all.

Dive deeper

Each option has pros and cons.

Paper bags are simple and cost-effective, but they may tear when wet.

Certified compostable bags are ideal but cost slightly more.

Going bag-free saves money and avoids confusion.

In my home, I use compostable PLA bags for kitchen waste, then rinse the bin after each collection. It’s simple, hygienic, and sustainable.

Why are there no compostable bags in the green bin?

Many people expect to see compostable bags accepted everywhere, but the system isn’t ready yet.

Some regions don’t allow compostable bags because local facilities cannot process them or identify them correctly.

Dive deeper

Composting plants often separate all plastics—even compostable ones—because they lack sorting technology.

This is changing slowly as governments introduce clearer waste rules.

At PackagingMC, we provide materials tested for compliance with global standards like EN13432 and ASTM D6400, so our clients can confidently meet regulations.

Conclusion

Biodegradable packaging is not just a trend. It’s a necessary shift toward a cleaner, safer, and more responsible future for our planet.